Deposition of epitaxial films of multicomponent compounds by magnetron sputtering, with YBa2Cu3O7-δ as an example.

With the high-temperature superconductor YBaACADEMY OF SCIENCES USSR

Technical Physics 38(7).

July 1993. p. 176-186

offprint (rus))

The development of microelectronics brings to the fore the problem of high-quality films of complex chemical composition corresponding to the phase diagram of the compounds, having special properties such as high-temperature superconductivity, semiconducting properties, ferromagnetism, and others. One of the promising techniques by which it possible to unify the deposition of various materials is magnetron sputtering. 1

This paper discusses the technological aspects of magnetron sputtering for obtaining high-quality films of the high-temperature superconductor YBa2Cu3O7 -δ

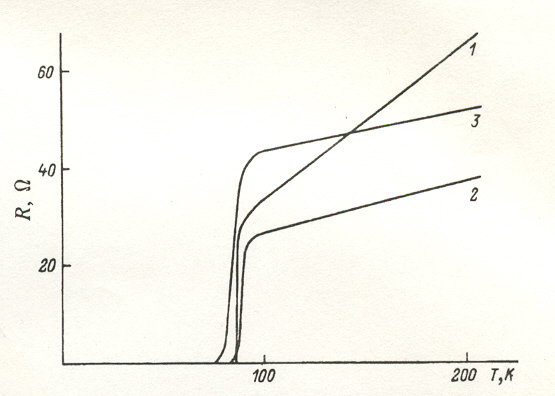

The preparation of thin films of YBa2Cu3O7 -δ by magnetron sputtering of stoichiometric targets has been described in the literature. 1 - 8 We have obtained high-quality superconducting films with the onset of the resistance drop (Fig. 1) at 95 K and have obtained zero resistance at 85-89 K for oriented SrTiO3 substrates, at 82-85 K for MgO substrates, and 75-79 K for silicon substrates with a buffer layer of ZrO2 by means of magnetron sputtering using a system shown diagrammatically in Fig. 2.

The sputtered target was a ceramic disk of composition YBa2Cu3O7 -δ of diameter 40 mm and a thickness of from 2 to 4 mm, which was attached by a silver contact to the cathode.

The total pressure of the argon -oxygen mixture with an Ar/O2 ratio between 3 and 10 was maintained at 0.2 to 0.4 torr and was monitored by means of a movable-electrode gas-filled tube with an accuracy of 10%. In addition, the rate of flow of argon directly into the discharge space was monitored, as was the supply of oxygen at a distance of several centimeters from the substrate. It was shown that to obtain high-quality films the rate of flow of argon from the magnetron must exceed the order of magnitude of 104 cm/s.

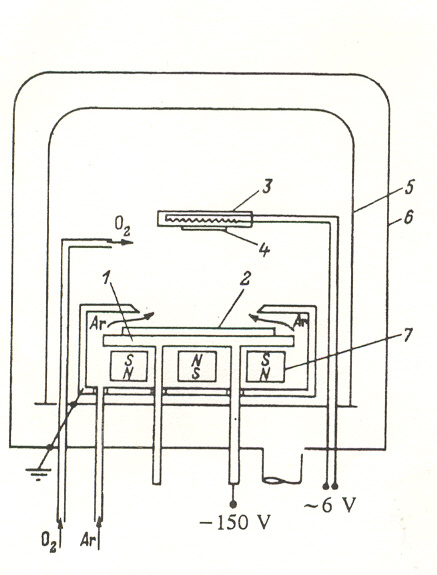

FIG. 1. Diagram of the magnetron sputtering system. 1) cathode; 2) sputtered target; 3) heating element; 4) substrate; 5) inner cover; 6) vacuum chamber wall; 7) magnetic system The magnetic system ensures a stable annular discharge with a ring diameter of 25 mm and a width of 6 mm. In steady-state discharge the discharge voltage lies between 140 and 160 V. An increase in the discharge voltage indicates that either the resistance of the target is increasing because of heating and the reduction of its oxygen content below that which gives it its high conductivity, or because of the pulverization of the anode ring, as a result of which the voltage drop at the anode increases.

The substrates were positioned at a distance of 22 to 28 mm from the target on a heater 9 consisting of a high-alumina ceramic into which a platinum or a nichrome wire was impressed at a temperature of 1200°C. The temperature of the substrate was monitored with a Pt/Pt+ l0%Rh thermocouple attached to a control substrate, which allowed measurement of the true substrate temperature during the deposition with allowance for the thermal barrier between the surface of the heater and the substrate in vacuum, which was usually found to be in the range 200-300°C.

The temperature of the substrate surface during the deposition was maintained in the range 650-750°C with the film deposited at a rate of 1.5 - 5 nm/s. After admission of oxygen to a pressure of 1 atm the sample was saturated with oxygen at a temperature of 550°C, with subsequent cooling to 400°C at a rate of about 5 degrees per min.

Deviations from these technological parameters resulted in irreversible degradation of the film quality. It is of interest to analyze the technological conditions of the deposition of single phase coatings for the purpose of creating a theoretical basis for a systematic optimization of the apparatus configuration and the technological conditions in formulating the problem of obtaining high-quality films on substrates having dimensions of the order of a square decimeter and greater.

The main advantage of magnetron sputtering systems is that the fluxes of the evaporating atoms are in the same ratio

FIG. 2. Temperature dependence of the resistance of YBaa2Cu3O7 -δ films prepared by magnetron sputtering onto a substrate of SrTiOj (1), MgO (2), and Si, with a protective coating of ZrO2 (3). as the composition of the target. Let us consider the expression for the flux of atoms of the itth species in the target for a discharge that etches away the surface at a velocity Vetch. According to Fick's law, the expression for the flux of atoms at a distance x from the surface of the target in a system of coordinates moving with the velocity of etching of the target is

(1) where ci(x) is the concentration of the ith component of the target at a distance x from the target and Di(x) is the diffusion coefficient of the ith atom.

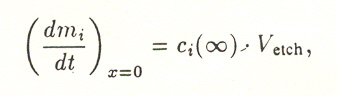

Under steady-state conditions, when the rate of sputtering Vetch is greater than the diffusion rate of the atoms in the target the concentration gradient of the atoms will be zero at a sufficiently large distance from the target surface and expression (1) can be reduced to the following expression for the fluxes of the evaporating atoms

(2) where ci(∞) is the concentration of the ith component sufficiently far from the target surface and is equal to the initial concentration in the target under steady-state conditions.

Since the value of Vetch is the same for each species of atom, it can be said that for the steady-state case the ratios of the fluxes of the evaporating atoms correspond to the initial composition of the target.

If the target is replaced or if the discharge current is changed it can take several hours to reestablish a steady-state discharge regime characterized by a steady-state distribution of the atoms in forepart of the target surface. A suitable criterion for the establishment of steady-state conditions is the attainment of a constant discharge voltage. An important technological factor that permits attainment of the steady-state regime of sputtering is good thermal contact between the target and the water-cooled cathode, which can be obtained by the use of silver contact paste. If the thermal contact is poor the target is heated by the discharge and the diffusion rate then increases exponentially and above a certain temperature can exceed the rate of sputtering, and as a consequence it is not possible to achieve a steady state at all.

At the time of the sputtering of the target a groove is formed in the discharge region with a configuration that determines the geometry of the emission of the target atoms. As the target is continually operated the width of the planar bottom of the groove, which permits the atoms to be emitted perpendicular to the plane of the target, decreases in size and finally disappears altogether, after which the cross section of the groove takes the form of a semicircle. At this point in time the rate of transport of atoms to the substrate falls off abruptly and the stoichiometry of the deposited film is perturbed to the extent that a new target is needed. The characteristic time that a target with a 6 mm groove can be used at a current density of 2 nm/s before it must be replaced is 100 h.

The target atoms ejected by argon ion bombardment have an energy of the order of 1 to 10 eV, which is much greater than the energy of thermal motion, 0.02 eV. As a result of collisions of these atoms with argon atoms the former lose energy, and when their energy is close to the thermal energy there is a transition from directed transport of target atoms to random transport obeying the laws of diffusion.

Depending on the energy of an atom that reaches the substrate, it can interact with the substrate surface in various ways, from being incorporated into the crystal structure to being reflected or even causing secondary sputtering of the target surface in the case of especially high-energy particles. Let us consider the transport of sputtered high-energy atoms from the target to the substrate.

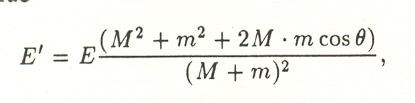

Let us say that the atom ejected from the target has a mass M, a radius R, and an energy E. As the result of a collision with an atom of the scattering gas, which has a mass m and radius r, the energy of the first atom is reduced to the value 10

(3) where (θ is the angle of separation in the center-of-mass coordinate system of the colliding particles.

The angle α of deviation of the particle from its initial direction can be calculated by the formula:

tg α = m Sin θ/(M + m*Cos θ) (4) An exact calculation of the scattering angles of atoms in random collisions requires the generally unavailable knowledge

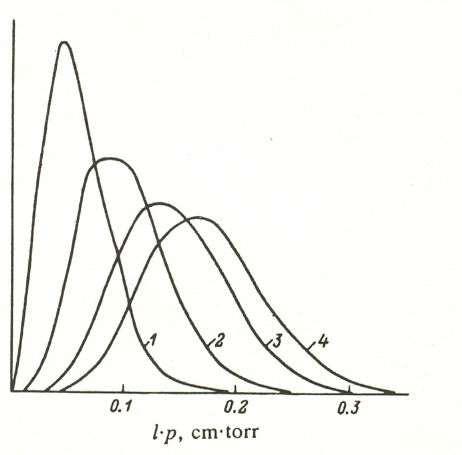

FIG. 3. Statistical curves of the reduced distance traveled by yttrium atoms in argon until they have lost 90% (I), 99% (2). 99.9% (3), and 99.98% (4) of their initial energy.

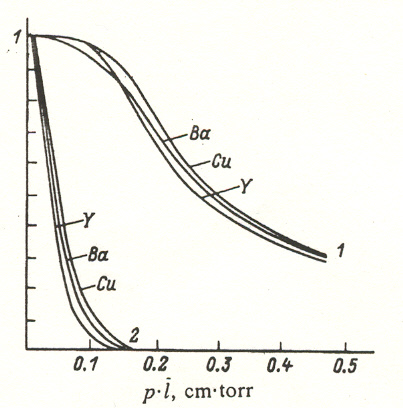

FIG. 4. Transport coefficients (I) and the fraction of atoms that have lost no more than 90% of their initial energy (2) during magnetron sputtering as functions of the reduced distance. of the interaction potential of the colliding particles. Therefore this treatment uses the simplest model for the determination of the angle of separation for random collisions, based on the assumption that the angle q depends linearly on the distance between the vector of the direction of motion of the particle and the center of mass of the scattering atom. When the collisions are random the angle can be calculated according to the formula

θ = (1 - √δ)*π (5) where d is a random quantity taking on values uniformly distributed in the interval from 0 to 1.

The distance a particle travels between two collisions is called the free path and can be calculated from the formula

l = ln δ/nσ = - λ ln δ (6) where σ is the collision cross section equal to σ = π(R + r)2, n is the concentration of atoms in the scattering gas, and l is the mean free path, equal to λ = 1/(nσ).

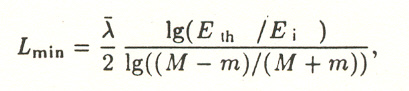

Figure 3 shows statistical curves of the distribution of yttrium atoms scattered by argon atoms, plotted by means of a program that uses the formulas given here to determine the distance travelled by an atom before it is thermalized, when its energy is less than a predetermined value, and to determine the amount that the atom deviates from its initial direction of motion. Unlike the model advanced by Danilin, 11 where all the collisions result in the maximum energy loss and the thermalization distance is determined by the formula

(7) in the present case, where non-head-on collisions are also taken into account, the average thermalization distance is 4-6 Lmin, and complete thermalization occurs at a distance of 12 - 14 Lmin.

After thermalization the transport of atoms occurs by diffusion, and in the case of the model where the target and substrate are two infinite parallel planes the probability of deposition of an atom on one of them is inversely proportional to the distance of the plane from the position of thermalization.

Then the probability of transport of an atom ejected from the target to the substrate is equal to

Pn = lth/L (8) where lth is the distance an atom travels before thermalization and L is the spacing between the target and the substrate.

Using formulas (3)-(6) and (8) we can calculate the transport coefficient of atoms of various species under conditions that are characteristic of real deposition.

According to Danilin, 11 bombardment by argon ions transfers to the target atoms 5 to 10% of the energy of the bombarding ions. With a discharge potential of 150 V the energy of the sputtered atoms is estimated to be 10-20 eV, while their energy of thermal motion at 500 K, which is the characteristic temperature in the region of the discharge, is 0.02 eV (i.e., 10-1 % of the initial energy).

Figure 4 shows the dependence of the transport coefficient of atoms of Y, Ba, and Cu for these conditions, plotted as a function of the spacing between the substrate and the target normalized to the pressure (the reduced spacing). This figure also shows curves that characterize the fraction of Y, Ba, and Cu atoms that have not lost more than 10% of the initial energy ( ~ 1 eV) as a function of the reduced spacing. The characteristic distance at which there are no particles with this high energy coincides with the luminescent flare above the magnetron during the discharge.

Depending on the reduced target-substrate distance one can describe the following characteristic cases of deposition of films from a YBa2Cu3O7-δ target.

In the region of existence of high-energy ions, L < 0.3 cm.torr, the films that are deposited are superconducting, but with a critical temperature Tc no higher than 70-75 K on SrTiO3 substrates. According to the calculations, at this distance there is nearly 100% transport of atoms from the target to the substrate, but the high energy of many of the atoms that reach the substrate either causes defects in the film or results in the reflection of the atom and its removal without incorporation in the growing film, and thereby the stoichiometry of the transport is disturbed.

At a reduced spacing L > 1 cm.torr all the atoms that reach the substrate are thermalized and can be incorporated into the film, which grows in the case of stoichiometric transport in the form of defect-free crystals. The transport coefficients of the various atoms can with a certain accuracy be calculated from the formula

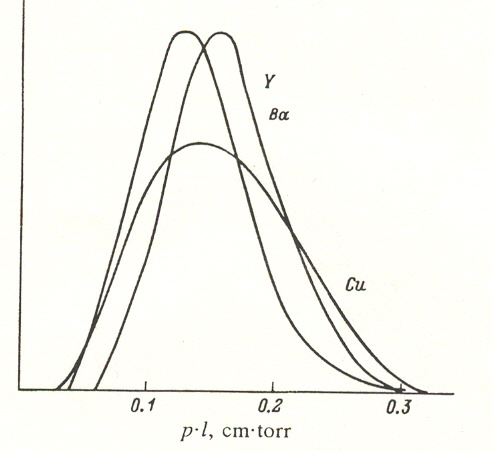

TCi = Li/L (9) where Li is the mean thermalization length of an atom of the ith species and can be determined from data on the fluctuations in the distribution of the thermalized Y, Ba, and Cu atoms as shown for (Eth/Ei) = 10-3 in Fig. 5.

With increasing target-substrate spacing the ratio of the transport coefficients for the different atoms becomes constant. For a stoichiometric YBa2Cu3O7 -δ target one should obtain under these conditions transport of a composition that can be expressed by the formula YBa2.4Cu3.3O7 -δ Accordingly, to obtain stoichiometric films the process may be carried out using an adjusted-charge mixture of composition Y1.2Ba2Cu3.25Ox for the target.

FIG. 5. Statistical curves of the reduced distances traveled atoms of the target YBa2Cu3O7 -δ until they have lost 99,9% of their initial energy, Carrying out the deposition with an adjusted charge mixture for the target by means of dc magnetron sputtering has the disadvantage that if the composition of the target departs from stoichiometry its conductivity falls and the stability of the discharge can be disrupted. Moreover, this treatment does not take into account the unavoidable fluxes of sputtering and reaction gases, which can have a substantial effect on the transport coefficients that are actually observed and are characteristic of a specific design of the sputtering system and deposition geometry.

Good results are provided by a deposition system in which the substrate is placed parallel to the direction of motion of the high-energy atoms. 12 In this orientation the substrate escapes bombardment by nonthermalized atoms, and if the substrate is located at a distance. less than Li the quantity TCj turns out to be close to 100%. Since the values of Li for atoms of different kinds in the present case do not differ by more than 20%, one can expect stoichiometric transport of the composition of the target when the substrate is located at a distance between Lmin and L from the target.

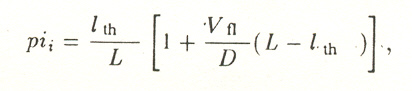

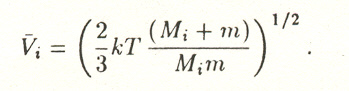

If the velocity of gas flow in the region of diffusion transport of thermalized atoms is comparable with the thermal velocity of the atoms, the expression for the probability of a thermalized atom reaching the substrate for a flow velocity Vfl in the direction from the target to the substrate takes the form

(10) where Di is the diffusion coefficient of the ith kind of atom, which is approximately equal to

Di = (1/3) * Viλi (11) where Vi is the average thermal velocity of the atoms of the ith kind in the gas, equal to

(12) If the crystallites that are nucleated have the same orientation their rates of growth normal to the substrate surface also turn out to be the same and smooth films are formed with a well-formed structure. If the substrate exerts no orienting effect or if there exists large supercooling at reduced temperatures, where the orienting effect of the substrate has little influence during the nucleation, the normal component of the rate of growth of each crystallite depends on its accidental orientation and can vary over a wide range, and consequently the films grow with a rough surface.

Mar. 4, 2018; 17:00 EST